Inspection Equipment

Process of Investment Casting, Investment Castings Process

C & S metal products Co. Ltd. is an ISO 9001:2008 certified manufacturer. We have built quality control procedures into the production process at every stage, to control the casting qualities.

We guarantee the chemical compositions and physical mechanical properties of the castings are qualified. These tests are according to the specifications of ASTM A216, A351 and DIN 17245,17445 etc., and we provide the testing certificate DIN EN 10204 3.1B.

You can get more information about process of investment casting, investment castings process, investment casting processes, investment casting lost wax process, lost wax investment casting process.

Spectrograph analyzer

Spectrograph analyzer1. Operation spec: ASTM A216, A351, DIN 17245,17445, etc.

2. Each melt, melt composition sampler verify.

3. The composition sampler kept for at least 2 years

Solid Cast Software

Solid Cast Software 1. Improve success rate on the first casting poured.

2. Eliminate production quickly.

3. Reduce scrap.

4. Lower costs.

5. Reduce scrap.

6. Improve quality.

Universal tensile tester

Universal tensile tester 1. Operation spec: DIN 50125, 50145 and ASTM.

Micro-structure microscope

Micro-structure microscope 1. Operation spec: ASTM A262-91

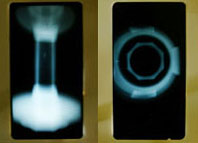

Radiography test

Radiography test 1. Operation spec: DIN 54111; ASTM E186/280/446

Liquid penetrant inspection

Liquid penetrant inspection 1. Operation spec: ASTM E165-80, SEP 1936

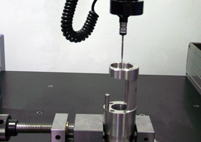

3D CMM

3D CMM1. 3D dimensional measuring systemequip with optical lens

Hardness tester

Hardness tester1. Operation spec: DIN 50351 and ASTM.

EM-2.5D system

EM-2.5D system